Abandoned Pipeline

An abandoned pipeline is one that is no longer being used by any pipeline operating company to transport natural gas or oil. Abandoned pipelines are usually left in the ground but are no longer used or maintained in a usable condition. They are emptied of oil or gas and filled with nitrogen, water, or some other non-flammable filler.

Technically speaking: An abandoned pipeline is a pipeline that has been physically separated from its source of gas or hazardous liquid and is no longer maintained under federal regulations. Abandoned pipelines are usually purged of the gas or liquid they transported and refilled with nitrogen, water, or a non-flammable slurry mixture. (Reference 49CFR 192.727 and 49CFR 195.59).

Abandonment

(1) Abandonment indicates that a company has received approval from the regulator to cease providing a particular service (e.g., to permanently shut down operation of a particular pipeline or facility) under that regulatory agency's jurisdiction.

(2) Abandonment also refers to the process and actions taken by a Company at the end of the useful life of a pipeline or pipeline facility to gain approval from the regulator. This process requires that the Company follow strict guidelines regarding how to prepare the pipeline or facility for permanent cessation of operation. The process often requires that the Company contact the landowners where the pipeline or facility is located and inform them of the planned actions. Details of the abandonment process can vary based upon when the pipeline or pipeline facilities were installed and what future abandonment requirements were agreed to at that time. These requirements range from abandonment in place to total removal.

Ability

The capacity to do or act, physically and/or mentally.

Abnormal Operating Conditions (AOC)

As defined in §§ 192.803 and 195.503.

Note: To be qualified, an individual must be able to properly perform assigned covered task(s) and be able to recognize and react appropriately to any AOC that may (reasonably be expected to) be encountered while performing the covered task – whether the condition arises as a direct result of his/her work performance (e.g., be specific to the covered task being performed) or not (e.g., be generic in nature, but still observable because the individual is present on site).

Accident

An accident is an unplanned occurrence that results in a release of oil or natural gas from the pipeline. Accidents can be expensive and can sometimes result in extensive property loss, environmental insult, injury and, sometimes, even death. Accidents can result from a lot of reasons, but the biggest reason is from damage to the pipeline resulting from digging.

Technically speaking: As used in pipeline safety regulations, accidents are failures occurring in liquid pipeline systems for which the pipeline operator must make a report to the Office of Pipeline Safety. Specific criteria defining events that are considered accidents are contained in 49CFR 195.50. Events or failures of similar magnitude related to gas pipelines are considered incidents and are defined in 49CFR 191.3.

Active Corrosion

Active corrosion is a term that indicates that pipeline corrosion is occurring now and is deteriorating the pipe.

Technically speaking: Active corrosion describes an ongoing electro-chemical process in which microscopic metal particles are removed from iron-based materials. Corrosion can occur in moist, aboveground atmospheric conditions but is more prevalent in underground environments. Active corrosion within the pipeline industry is a serious threat to pressure containing structures (i.e., steel pipelines) that, unless controlled, could result in leaks or failures.

See Also: Corrosion

Activity

A specific deed, action, function, or sphere of action.

Actuator

An actuator is a device that causes a valve to move from the open to the closed position or vice versa.

Technically speaking: A component designed to provide the mechanical energy to physically move a connected device. Actuators are used extensively to move valves to their open and closed positions. Valve actuators can be pneumatic, hydraulic, or electric motor driven and can be automated to respond to a remote control signal.

Aerial River Crossing

An aerial river crossing is a location where a pipeline is suspended to cross a waterway, either by cables over the waterway or attached to the girders of a bridge designed to normally carry vehicle traffic.

Affects the Operation or Integrity of the Pipeline

Any activity, or omission of an activity, that could directly or indirectly result in a hazard to persons, property or the environment. As used in the safety context of the OQ rule, the phrase indicates activities that could result in an abnormal operating condition that in turn could result in an unsafe operating condition.

AGA

See American Gas Association.

Alternating Current (AC)

Alternating current is the common form of electricity that we get in the United States when we plug an appliance into the wall. The form of electricity we get from flashlight batteries is known as direct current.

Technically speaking: Alternating current is an electrical current for which the current direction, or positive to negative flow (known as polarity), changes back and forth over a specified period of time. The frequency with which the current direction alternates is measured in cycles per second and is referred to as 'hertz.' In North America, the common frequency is 60 hertz, which indicates that the current direction or polarity changes back and forth 60 times per second.

American Gas Association (AGA)

From the web site of the American Gas Association:

The American Gas Association represents 200 local energy utility companies that deliver natural gas to more than 64 million homes, businesses and industries throughout the United States. AGA's members� deliver 92 percent of all natural gas provided by the nation's natural gas utilities. AGA is an advocate for natural gas utility companies and their customers and provides a broad range of programs and services for member natural gas pipelines, marketers, gatherers, international natural gas companies and industry associates.

American National Standards Institute (ANSI)

From the web site of the American National Standards Institute:

The American National Standards Institute (ANSI) is a private, non-profit organization (501(c)3) that administers and coordinates the U.S. voluntary standardization and conformity assessment system. The Institute's mission is to enhance both the global competitiveness of U.S. business and the U.S. quality of life by promoting and facilitating voluntary consensus standards and conformity assessment systems, and safeguarding their integrity.

American Petroleum Institute (API)

From the web site of the American Petroleum Institute:

The American Petroleum Institute (API) is the major national trade association representing the entire petroleum industry: exploration and production, transportation, refining, and marketing. With headquarters in Washington, D.C., and petroleum councils in 33 states, it is a forum for all parts of the oil and natural gas industry to pursue priority public policy objectives and advance the interests of the industry in a legally appropriate manner.

American Society of Mechanical Engineers (ASME)

From the web site of the American Society of Mechanical Engineers:

The American Society of Mechanical Engineers (ASME) conducts one of the world's largest technical publishing operations, holds some 30 technical conferences and 200 professional development courses each year, and sets many industrial and manufacturing standards. Founded in 1880 as the American Society of Mechanical Engineers, today ASME International is a nonprofit educational and technical organization serving a worldwide membership.

Anode

An anode is the pole or terminal from which current flows in a direct current electrical circuit. In an electrical cell or battery(such as a flashlight battery), the anode is recognized as the negative terminal. When a completed circuit exists (as when you turn on the flashlight), electrical current flows from the negative terminal (the anode) through the circuit to the positive terminal (the cathode). Along the way, the current lights the flashlight bulb. As the anode gives up electrons it deteriorates, or corrodes.

Technically speaking: An anode is the electrode in an electrochemical corrosion cell where oxidation or corrosion occurs and from which current flows. In a pipeline-related cathodic protection system, the anode is the sacrificial material or electrode having low electrolytic potential. Current flows away from the anode, causing it to corrode. Corrosion of the anode protects a nearby structure (pipeline, tank bottom, or other underground structure) having higher electrolytic potential from corroding.

Anomaly

An anomaly is something that is identified that normally should not be there. For example, a hole in your sock could be considered an anomaly.

A pipeline anomaly is generally thought of as an imperfection in the wall of the pipe. Many pipeline anomalies result during the pipe manufacturing process and don't affect the performance of the pipeline or its ability to function in a safe manner. Other pipeline anomalies are caused by corrosion or damage to the pipe from outside forces like digging equipment. Some of these can be detrimental to the integrity of the pipeline if not repaired.

Technically speaking: An anomaly is a possible deviation from otherwise sound material in a pipe or weld. Indication of an anomaly may be determined by nondestructive examination, such as inline inspection.

ANSI

See American National Standards Institute.

API

See American Petroleum Institute.

Accountable Pipeline Safety and Partnership Act (APSPA)

The Accountable Pipeline Safety and Partnership Act of 1996 (APSPA) was to reduce risk to public safety and the environment associated with pipeline transportation of natural gas and hazardous liquids, and for other purposes. In part, the APSPA required the U.S. Department of Transportation to conduct a four-year Risk Management Demonstration Program (RMDP) in which pipeline operating companies were selected to demonstrate pipeline risk management processes.

The RMDP was designed to test whether a formalized process for identifying pipeline-specific risks, allocating resources to the most effective risk control activities, and monitoring safety and environmental performance, can lead to superior safety and environmental protection, greater levels of public participation in the regulatory process, a more informed and effective regulator, and increased efficiency and reliability of pipeline operations.

The RMDP was designed to test assumptions through a set of demonstration projects to be conducted with interstate pipeline operators. A report was submitted to Congress in December 2000 describing the RMDP progress and lessons learned.

ASME

See American Society of Mechanical Engineers.

Association of Oil Pipelines (AOPL)

From the web site of the Association of Oil Pipelines:

The Association of Oil Pipe Lines (AOPL) is an unincorporated nonprofit organization started in 1947. As a trade association, the AOPL: - Acts as an information clearinghouse for the public, the media and the pipeline industry. - Provides coordination and leadership for the industry's ongoing Joint Environmental Safety Initiative. - Represents common carrier crude and product petroleum pipelines in Congress, before regulatory agencies, and in the federal courts.

ASTM International

From the web site of the ASTM International:

Founded in 1898, ASTM International is a not-for-profit organization that provides a global forum for the development and publication of voluntary consensus standards for materials, products, systems, and services. Formerly known as the American Society for Testing and Materials, ASTM International provides standards that are accepted and used in research and development, product testing, quality systems, and commercial transactions around the globe.

Atmospheric Corrosion

Atmospheric corrosion is a chemical attack on exposed metal surfaces by elements in the air. A common form of atmospheric corrosion is known as rust. Rust commonly occurs when a ferrous metal (iron), such as a nail, is exposed to moist air.

Technically speaking: Atmospheric corrosion affects aboveground pipeline or components that are exposed to the atmosphere and is a chemical change in the pipe or component material resulting from the material's interaction with the atmosphere. Most commonly this interaction causes the oxidation of metal.

See Also: Corrosion

Automatic Control Valve

An automatic control valve is a valve that controls the flow of oil or natural gas in a pipeline and that opens or closes automatically in response to some signal.

Technically speaking: An automatic control valve is one that closes automatically in response to a pressure loss or a flow rate increase, either of which exceeds a predetermined set point.

Backfilling

Backfilling means filling the dirt back into a ditch or hole you previously dug.

Technically speaking: Backfilling is the process of filling the trench where a newly constructed or recently unearthed pipeline is installed. Adequate fill material is provided and compacted around the pipe to completely fill the excavation and to ensure that the pipe is properly supported and not subjected to added stresses due to soil subsidence or movement.

Barrel

(1) A barrel is a standard measure of a volume of oil and is equal to 42 gallons.

(2) A beginning point or end point of a pipeline is sometimes referred to as a barrel. Barrels are designed with opening closures similar to doors that allow the pipeline operator to insert inline inspection tools into the pipelines. Barrels where pigs are inserted into the pipeline are called launchers and barrels where pigs are retrieved and taken out of the pipeline are called receivers.

49CFR 194.5 and 49CFR 195.2

Baseline Assessment Plan

A baseline assessment plan (BAP) is the plan a pipeline operator must develop to assess the integrity of all of the lines included in its integrity management program. The BAP must show when each line is to be assessed and the assessment method the operator will use.

Technically speaking: The baseline assessment plan is an integral part of an operator's pipeline integrity management program. The BAP must, as a minimum: 1) identify all segments of a pipeline system that could impact a High Consequence Area (HCA); 2) identify the specific integrity assessment method(s) to be conducted on those segments; 3) specify the schedule by which those integrity assessments will be performed; and 4) provide the technical justification for the selection of the integrity assessment method(s) and the risk basis for establishing the assessment schedule. (Reference 49CFR 195.452).

Bell Hole

A bell hole is a hole dug into the ground over or alongside a pipeline to allow the line to be examined and to provide room for workmen to perform maintenance on the pipeline. In a broader sense it is any hole, other than a ditch, that is opened for pipeline work.

Technically speaking: A bell hole is an excavation made to permit a survey, inspection, maintenance, repair, or replacement of pipe sections. It is so called because of its upside-down bell shape, wide at the top and narrowing to a smaller diameter around the pipeline to be examined. The walls of the hole are angled according to OSHA rules to prevent cave-ins and risks to worker safety.

Bend Radius

Bend radius is the measurement of the radius of a bend in a pipeline. Bends can be included in the manufacture of the pipe or created in the field during construction and installation of a pipeline.

Block Valve

A block valve is a mechanical device (valve) installed in a pipeline that can be closed to block the flow of oil or gas through the line.

Technically speaking: A block valve is a valve used to stop the flow of product through a pipeline and isolate a segment of the pipeline system or a component of the system.

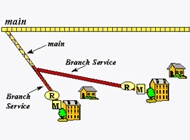

Branch Service Line

A branch service line is a service line in a natural gas distribution system that branches off of a main line or another service line.

Technically speaking: In natural gas distribution systems, branch service line is a line that branches off of another service line; thereby changing the classification upstream of the branch point from a service line to a main.

Breakout Tank

A breakout tank is a tank used to temporarily store oil in a pipeline system.

Technically speaking: A breakout tank is a tank used to relieve surges in a hazardous pipeline system or to receive and store hazardous liquids transported by the pipeline for later re-injection and continued transportation by the pipeline.

Reference 49CFR 194.5 and 49CFR 195.2

Buckle

A buckle is an anomaly that represents a partial collapse of the pipe wall and is usually caused by excessive bending or curvature being applied to the pipe. Depending on the severity of the buckle, it may represent an undesirable anomaly that can cause localized stress concentrations and must be repaired.

Technically speaking: A buckle is a partial collapse of the pipe wall due to excessive bending associated with soil instability, landslides, washouts, frost heaves, earthquakes, etc. Buckles can also occur in pipeline construction during a field bending operation using a side boom. Buckles cause localized stress concentrations and must not be installed in new construction or, if found, must be removed from existing systems.

See also: Wrinkle

Bulkhead

A bulkhead is a wall built or installed along a coastline or waterway to protect an adjacent pipeline from washout or soil erosion.

Bureau of Land Management (BLM)

From the web site of the Bureau of Land Management:

The Bureau of Land Management (BLM) is an agency in the Department of Interior, in the US Government. The BLM manages 264 million acres of surface acres of public lands located primarily in the 12 Western States, including Alaska. The agency manages an additional 300 million acres of below ground mineral estate located throughout the country. The BLM administers public lands within a framework of numerous laws. The most comprehensive of these is the Federal Land Policy and Management Act of 1976 (FLPMA). All Bureau policies, procedures and management actions must be consistent with FLPMA and the other laws that govern use of the public lands. It is the mission of the Bureau of Land Management to sustain the health, diversity and productivity of the public lands for the use and enjoyment of present and future generations.

Caliper Tool

A caliper tool is an adjustable measuring tool that can be used to measure the thickness of an object, the diameter of a circle, or the distance between two surfaces. Hi-tech variations of these tools are used to measure the inside diameter of a pipe and record variations in that diameter.

Technically speaking: A caliper tool is an inline inspection device that measures deviations in the geometry of a pipeline's internal surface. A caliper tool uses a set of mechanical fingers that ride against the inside diameter of the pipe and record deviations caused by the relative movement of these fingers as the tool passes through the pipe

Corrective Action Order (CAO)

PHMSA may issue a Corrective Action Order if it determines that a particular pipeline represents a serious hazard to life, property, or the environment. They usually address urgent situations arising out of an accident, spill, or other significant, immediate, or imminent safety or environmental concern. In a Corrective Action Order, PHMSA identifies actions that must be taken by the operator to assure safe operation. These actions may include the shutdown of a pipeline or operation at reduced pressure, physical inspection or testing of the pipeline, repair or replacement of defective pipeline segments, and similar measures. Corrective Action Orders are described in 49 CFR 190.233.

Carbon Dioxide (CO2)

Carbon dioxide is a naturally occurring gas that is transported and used in the petroleum industry. Carbon dioxide is a heavy gas that can displace breathing air and breathing carbon dioxide can be hazardous to your health.

Technically speaking: Carbon dioxide is a naturally occurring gas consisting of molecules formed of one carbon and two oxygen atoms. Carbon dioxide is a heavy gas that is transported by pipeline as a compressed fluid consisting of more than 90% carbon dioxide molecules. If released into the atmosphere from a pipeline leak carbon dioxide is considered hazardous due to its ability to displace breathing air. (Reference 49CFR 195.2)

Carbon Steel

All steel is formed as an alloy of iron and carbon and may contain small quantities of other elements. However, 'carbon steel' is steel for which the content of elements other than iron is not specified and the content of manganese or copper does not exceed specified amounts.

Technically speaking: All steel is formed by alloying iron with carbon. Steel is commonly considered to be carbon steel when:

(1) no minimum content is specified or required for aluminum, boron, chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium, zirconium, or any other element added to obtain a desired alloying effect;

(2) the specified minimum content does not exceed 1.65% for manganese or 0.60% for copper. All carbon steels may contain small quantities of unspecified residual elements unavoidably retained from raw materials. These elements (copper, nickel, molybdenum, chromium, etc.) are considered incidental and are not normally determined or reported.

Cast Iron

Cast iron is iron that is cast (heated to melting and poured into molds) and in which the carbon molecules in the metal are not bonded with the iron molecules. Cast iron is brittle and can crack. It is not suitable for high-pressure applications.

Technically speaking: Cast iron applies to gray cast iron, which is a cast ferrous material in which a major part of the carbon content occurs as free carbon in the form of flakes interspersed through the metal. Because the carbon flakes do not bond with the ferrous material on the molecular level, the metal is brittle and susceptible to stress cracking under pressure situations. Many older, low-pressure gas systems were constructed with cast iron pipe.

In 2011 PHMSA appealed to all pipeline safety stakeholders for help to increase pipeline safety awareness and repair, rehabilitate, and replace aging infrastructure. This involves the replacement of cast/wrought iron pipe. In 2012, PHMSA officials again emphasized to each State the importance of eliminating aging infrastructure.

Cathode

Simply speaking, a cathode is the pole or terminal to which current flows in a direct current electrical circuit. In an electrical cell or battery (such as a flashlight battery), the cathode is recognized as the positive terminal. When a completed circuit exists (as when you turn on the flashlight), electrical current flows from the negative terminal (the anode) through the circuit to the positive terminal (the cathode). Along the way, the current lights the flashlight bulb.

Technically speaking: A cathode is a component of an electrochemical corrosion cell. It is the metal that attracts ions and gains mass through the corrosion process. In a cathodic protection system, the pipeline acts as the cathode and is protected from corrosion by the sacrificial activity of the anode.

Cathodic Protection (CP)

Cathodic protection is a method of protecting metallic pipelines from corrosion.

Technically speaking: Cathodic protection is a method of corrosion prevention in which the pipeline is allowed or made to act as the cathode in an electrochemical corrosion cell. A sacrificial anode having a lower electrolytic potential than the pipe is provided to complete the cell. The same electrolytic action that causes the anode to corrode protects the cathode (the pipeline or other component) from corroding.

Cathodic Protection Monitoring or Survey

Monitoring cathodic protection systems is an activity performed by pipeline operators to assess the adequacy of cathodic protection on the pipeline.

Centering

Centering is a method of determining the approximate location of a pipeline leak.

Technically speaking: The process of approximating the location of a pipeline leak. Centering can be done manually using gas detection equipment, such as acoustical equipment, or through a more sophisticated SCADA-based leak detection system using mathematical modeling of critical pressures, temperatures, flow-rates, etc. to predict volume loss and location estimates.

Centrifugal Compressor

Centrifugal compressors are pumps that are used to boost the internal pressure of gas pipelines. They are usually placed at key locations along the pipeline systems.

Check Valve

A check valve is a valve that allows liquids or gases in a pipeline to flow in one direction but closes to prevent flow in the opposite direction. These types of valves are used extensively in the pipeline industry to prevent reverse-flow or back-flow in the event of a pipeline leak or abnormal operating occurrence.

Class Location

Class location refers to a regulatory designation for natural gas transmission pipelines that indicates the level of human population within a certain distance on either side of the line. The class location of a pipeline is a factor in determining the maximum allowable operating pressure of the pipeline.

Technically speaking: Class location is a criterion for gas pipeline design set by the U.S. Code of Federal Regulations, 49CFR 192.5. A class location is based on the number and type of buildings intended for human occupancy that are situated in an area that extends 220 yd (200 m) on either side of the centerline of any continuous 1.0-mile (1.6-km) length of a gas pipeline. Class locations are specified as Class 1, 2, 3 or 4. Class 1 indicates the least heavily populated of the class locations, representing an offshore area or an area with 10 or fewer buildings intended for human occupancy. In comparison, Class 4 indicates the most heavily populated of the class locations, representing an area where buildings with four or more stories above ground are prevalent.

Cleaning Pig

A cleaning pig is a device that is placed inside a pipeline to remove unwanted debris from the inside of the pipeline. The pig can be drawn or pushed through a pipeline but often is moved through the line as a result of the flow of the product in the line. A type of utility pig, a cleaning pig uses cups, scrapers, or brushes to remove dirt, rust, mill scale, and other debris from the internal surface of a pipeline. Cleaning pigs are used periodically or as necessary to increase the operating efficiency of a pipeline or to facilitate inspection of the pipeline.

Close Interval Surveys (CIS)

A close interval survey is a method of testing corrosion protection systems on pipelines. It involves inspection and electrical testing of the corrosion protection system every two to three feet along the pipeline to confirm the status of the protection system and to help identify mechanical damage to the pipeline.

Code of Federal Regulations (CFR)

Federal regulations are published systematically (codified) in the Code of Federal Regulations (CFR). The CFR is the official compilation of the federal regulations of general applicability and legal effect. The CFR is divided into 50 titles that represent broad topical areas that are subject to federal regulation. For example, Title 49 covers Transportation, Title 10 covers Energy, and Title 34 covers Education.

Each title is divided into volumes, sections, parts, or chapters. Those may be further divided and grouped into subtitles, chapters, subchapters, parts, subparts, or divisions. Specific chapters or parts within each title are devoted to agencies having regulatory authority in that major area, in which all of that agency's regulations are codified.

For example, under Title 49, Transportation, the current pipeline safety regulations are codified as Parts 186 through 199, under Subchapter D, Pipeline Safety. Subchapter D is under Chapter 1, Pipeline and Hazardous Materials Safety Administration, Department of Transportation.

Title 49 of the Code of Federal Regulations.

Commercially Navigable Waterway

A commercially navigable waterway is a waterway where there is a substantial likelihood of commercial navigation. These waterways are identified in the National Waterways Network, a geographic database created by the National Waterways GIS Design Committee. The database is available from the U. S. Department of Transportation, Bureau of Transportation Statistics.

Common Ground Alliance (CGA)

From the web site of the Common Ground Alliance:

The Common Ground Alliance (CGA) is a nonprofit organization dedicated to shared responsibility in damage prevention and promotion of the damage prevention Best Practices identified in the Common Ground Study Report. The purpose of the CGA is to ensure public safety, environmental protection, and the integrity of services by promoting effective damage prevention practices.

Communicate

To convey information about; make known; to reveal clearly.

Compliance

Activity(ies) in accordance with a rule.

Component

A component in a pipeline system is any part of the system that is subject to the internal system pressure. System components must be designed to not leak; thereby assuring that the oil or gas is not released from the system and that the system operating pressure is maintained. Examples of components include the pipe, valves, flanges and other fittings.

Compressor Stations

Compressor Stations are facilities located along a natural gas pipeline which house and protect compressors. Compressors are used to compress (or pump) the gas to move it through the system. Compressor stations are strategically placed along the pipeline to boost the system pressure to maintain required flow rates.

Computational Pipeline Monitoring (CPM)

Computational Pipeline Monitoring is a method of monitoring the operation of a pipeline system. It makes use of a software-based monitoring tool that alerts the pipeline dispatcher of possible pipeline operating abnormalities that could indicate a commodity release.

Confirmation Digs

Confirmation digs are excavations performed at selected pipeline locations to expose the pipe to allow confirmation of the existence and characteristics of potential anomalies in the pipe wall that were identified by inline inspection techniques.

Consent Order

Once PHMSA has issued a Corrective Action Order or given notice to an operator of other proposed enforcement action, PHMSA and the operator may occasionally agree to the issuance of a Consent Order in lieu of a Compliance Order or the imposition of civil penalties. In a Consent Order, the operator agrees to the jurisdictional facts of the case and agrees to implement the specific actions in the Consent Order by the required deadlines. Should the operator not comply with the Consent Order terms, PHMSA can enforce its terms as the parties have agreed. Consent Orders can thus offer various advantages over more traditional enforcement remedies. They can expedite the resolution of cases, facilitate future enforcement action by PHMSA, and require operators to take additional measures beyond those required by regulation, thus achieving a greater level of safety. Consent Orders are described in 49 CFR 190.219.

Consensus Standards

Consensus standards are standards for performance that are established in open and voluntary forums by consensus of parties affected by the standards. These standards provide the best available professional guidance related to specific subjects. National consensus standards reflect the professional knowledge and judgment of people having appropriate experience, training, and education in the subjects to which the standards apply. The National Technology Transfer and Advancement Act (Public Law 104-113) mandates that Federal departments and agencies use voluntary consensus standards in place of Government standards wherever practical. There are consensus standards that apply to virtually all aspects of energy transportation pipeline design, construction, and operation. For example, some of the standards utilized by the pipeline industry provide guidance for manufacture of pipe, valves, and all other pipeline components; techniques and materials to be used in welding; and techniques to determine if existing pipeline corrosion has progressed such that the pipe is no longer safe to operate. Some organizations that produce consensus standards include: - American Petroleum Institute (API) - American National Standards Institute (ANSI) - ASTM International (ASTM) - American Society of Mechanical Engineers (ASME)

Consequence

A consequence is the result of some action or condition or series of events. A consequence may be observed directly, determined by investigation after an action or series of events has occurred, or determined by evaluation and analyses as the logical result of a postulated action or condition or series of events.

Technically speaking: A consequence is often noted as the cumulative, undesirable result of an accident. Consequences are usually measured in health and safety effects, environmental impacts, loss of property and/or business costs. Consequence descriptions may be qualitative or quantitative estimates of the effects of an accident.

Consequence Analysis

A consequence analysis is the evaluation or analyses of a postulated action or condition or series of events to determine the logical result. A consequence analysis may be performed to determine the expected effects of events leading to a pipeline accident, independent of the likelihood of such events occurring.

Continual Evaluation of Pipeline Integrity

Under pipeline integrity management regulations, pipeline operators must develop programs for conducting periodic pipeline integrity assessments and evaluating the results of those assessments to understand current pipeline conditions and identify integrity issues. This periodic assessment and evaluation cycle is recognized as a continual evaluation of pipeline integrity.

Contributed

Determined to be a factor.

Contributed to

A judgment by designated operator personnel, that the action or inaction of an individual(s) was a factor in the occurrence of an incident/accident.

Corrosion

Corrosion is the deterioration of a material, usually a metal, which results from a reaction with its environment. Common rust is an example of corrosion of iron. Steel pipe is subject to corrosion damage.

See Also: Active Corrosion, Atmospheric Corrosion, Corrosion Fatigue, Non-active Corrosion, Pitting, Selective Corrosion, Stress Corrosion Cracking (SCC), Uniform Corrosion

Corrosion Fatigue

Corrosion fatigue is a reduction of the durability of a pipe due to corrosion.

Technically speaking: Fatigue is a weakening of a material caused by the repeated application and removal of stress. For example, if you bend a piece of metal back and forth repeatedly in the same spot, fatigue will result at the bend location and will weaken the metal until it eventually breaks. Pipelines experience fatigue as a result of periodic increases (application of stress) and decreases (removal of stress) in operating pressures. Because fatigue can cause a failure to occur at stress levels well below those that a material can withstand in a single, non-repetitive loading, materials that must resist repeated stress cycles must be specially designed for this service. Durability is the ability of the material to resist fatigue. Corrosion fatigue is a reduction in a material's durability brought on by corrosion. Corrosion fatigue can cause the failure of a pipe at pressure below that for which the pipe was designed.

Cost/Benefit Analysis

A cost/benefit analysis is an evaluation and comparison of an activity's cost to its perceived benefits.

Technically speaking: A cost benefit analysis a determination and comparison of the expected costs to implement a proposed activity and the expected safety, environmental, or other benefits resulting from the activity. Cost/benefit analysis can be used to establish priorities among various activities, to compare and select among alternate ways of accomplishing an objective, or to decide whether a proposed activity should be implemented. The various expected benefits of a proposed activity are often translated into dollar values ('monetized') to allow different types of benefits to be combined and then compared with the costs of achieving these benefits. Cost/benefit analysis is used by regulators to justify new regulations, and by operators to define and allocate resources to operational and maintenance activities.

Cost/Benefit Ratio

A cost/benefit ratio is the ratio of the cost of performing an activity compared to the perceived benefits of performing it.

Technically speaking: The monetary costs required to complete a proposed activity (for example, replacing a section of pipe) divided by the monetized value of the benefits expected to be derived from that activity (for example, decreased pipe leak rate or likelihood of rupture). Cost/benefit ratios are usually used as an input to, but not sole determinate of, a decision to proceed with the proposed activity.

Council on Environmental Quality (CEQ)

From the web site of the Council On Environmental Quality:

The Council on Environmental Quality (CEQ) coordinates federal environmental efforts and works closely with agencies and other White House offices in the development of environmental policies and initiatives. The Council's Chair, who is appointed by the President with the advice and consent of the Senate, serves as the principal environmental policy adviser to the President and Vice President. In addition, CEQ reports annually to the President on the state of the environment; oversees federal agency implementation of the environmental impact assessment process; and acts as a referee when agencies disagree over the adequacy of such assessments. CEQ was established by Congress within the Executive Office of the President with passage of the National Environmental Policy Act of 1969. Additional responsibilities were provided by the Environmental Quality Improvement Act of 1970.

Covered Task

As defined in § 192.801 and § 195.501.

Cracks

Cracks are undesired openings or separations in a normally rigid material, such as a pipe wall. Often cracks are found only on the surface and do not fully penetrate the pipe wall. Using specialized equipment, cracks that may not appear on the surface of the pipe can be found within the thickness of the pipe wall. Regardless, cracks that don't fully penetrate the pipe wall and result in leaks are considered critical anomalies that could propagate into a leak or failure and must be repaired.

Technically speaking: Cracks in line pipe are separations in the molecular structure of the base metal and form as a result of improper manufacturing or operational stresses. Cracks are detrimental to the pipe's pressure restraining capabilities and can propagate into complete failure or rupture zones.

Criterion

A standard upon which a judgment is based.

Critical Bond

A critical bond is a wire connecting one pipeline to another, nearby pipeline to help prevent corrosion.

Technically speaking: Buried pipelines in close proximity or crossing over/under one another will often have different levels of cathodic protection and thus a strong possibility of different electrical potentials (voltage differences). If the soil resistance path between the pipelines is low, electrical currents will flow from one pipeline to the other. The pipeline with the current leaving will experience metal loss or corrosion. To prevent this occurrence, pipeline companies electrically connect or bond their pipes to one another using a copper wire. The wire provides an electrical path for the current to flow through rather than allowing current to flow off the pipe and into the soil, thus eliminating corrosion. The connecting wire is referred to as an electrical bond. Critical bonds are those that if not attached, would allow corrosion to occur and jeopardize the safe operation of one of the pipelines in question.

Critical Defect

A critical defect is an identified pipeline defect for which analysis indicates immediate attention is required.

Crude Oil

Crude oil is oil that is extracted from the ground before it is refined into usable products, such as gasoline.

Technically speaking: Crude oil is the raw liquid petroleum product extracted from oil wells. It is a mixture of thousands of chemicals and compounds, primarily hydrocarbons. Crude oil must be broken down into its various components by distillation before these chemicals and compounds can be used as fuels or converted to more valuable products. Crude oil is classified as either 'sweet crude' (sulfur content less than 0.5%) or 'sour crude,' (at least 2.5% sulfur).

Curb Valve

A curb valve is a valve installed in a natural gas service line and is used to shut off the gas supply to a building. Curb valves are installed underground at or near the property line, normally with protective curb boxes or standpipes installed over or around the valve. They are operated by use of a removable key or specialized wrench.

Current

(1) Current is the measure of the flow of electrons in an electrical circuit. Current is usually measured in engineering units called amperes, which indicate how much electrical energy is flowing through the circuit.

(2) Belonging to the present time; now in progress.

Damage Prevention Initiatives

In addition to enforcing Damage Prevention Regulations in the Code of Federal Regulations, the Office of Pipeline Safety has undertaken a variety of other initiatives to promote pipeline damage prevention. These initiatives, some of which involve collaboration with various stakeholder industry groups, promote public awareness of pipelines and other underground facilities; education of the public and emergency officials, excavators, emergency responders, legislators and other stakeholders on how to recognize and respond to pipeline leaks; and other aspects of pipeline safety. Some more notable recent efforts include: Dig Safely, Common Ground Alliance (CGA), and the One-Call Systems Study (OCSS).

Damage Prevention Regulations

Damage prevention regulations for pipelines are found in the Code of Federal Regulations. They require pipeline operators to implement programs to prevent damage to buried pipelines from excavation activities. The regulations specify requirements for operators to interact with the public near pipelines and with companies/persons likely to perform excavation near pipelines. Pipeline operators may comply with some of the regulatory requirements for damage prevention by participating in public service programs such as a one-call system. However, such participation does not relieve the operator of the responsibility of compliance to the regulation.

Defect

A defect is an imperfection that can cause an inadequacy or failure. In pipelines, certain types of defects have been known to cause failures. When defects are found in a pipeline that are characteristic of problem defects, they must be evaluated and, if necessary, repaired or removed to prevent future failures.

Technically speaking: A defect is an imperfection of sufficient magnitude in a pipeline that it should be analyzed using a recognized and approved engineering procedure, such as ASME B31G. Analysis determines if the defect is severe enough to require removal or repair, depending on prescribed operating requirements. Examples of defects include dents, corrosion pits, and cracks.

Demonstrate

Provide tangible evidence.

Dent

A dent is a depression in the pipeline surface caused by pressure or a blow. A dent does not reduce the thickness of the pipe wall. Dents are usually local depressions caused by outside mechanical force, such as the pipe resting on a rock or being hit by a backhoe. Pipeline repairs or replacement may be needed depending on the severity of the deformation.

Department of Transportation (DOT)

From the DOT web site:

A cabinet-level department of the executive branch of the federal government. The DOT is headed by the Secretary of Transportation, who is appointed by the President and confirmed by the Senate. The DOT is responsible for government involvement in all types of transportation, including transportation of hazardous liquids and natural gas by pipeline. Within the DOT, the Office of Pipeline Safety, part of the Research and Development Administration, is responsible for regulating pipeline safety.

The Department of Transportation can be contacted at 202-366-4000 or for more information see www.dot.gov.

Destructive Testing

Destructive testing refers to testing of a specimen in which the specimen is rendered unusable (i.e., destroyed) for its intended or practical use. Destructive tests are typically conducted on representative specimens to prove the strength or chemical characteristics of the sample piece.

Determine

Determine means to decide or settle conclusively and authoritatively. As used in pipeline safety regulations, determine means to establish that a condition actually or definitely exists, after evaluating by either investigation or calculation the potential for the condition to exist. There is a difference between identifying a potential condition and determining that the condition actually exists.

See also Discovery of a Condition.

Dig Safely

Dig Safely is the nationally recognized campaign to enhance safety, environmental protection, and service reliability by reducing underground facility damage. This damage prevention education and awareness program is used by pipeline companies, one-call centers, and others throughout the country. Dig Safely was developed through the joint efforts of the Office of Pipeline Safety and various damage prevention stakeholder organizations. Dig Safely is now within the purview of the Common Ground Alliance (CGA).

Direct

To take authoritative charge of or supervise; to control, order or command.

Direct Assessment

Direct assessment refers to a method of evaluating the integrity of a pipeline. Various indirect measurement tools are used to determine locations on the pipeline that may require direct examination to verify pipeline integrity. These locations are then excavated and examined to verify that the pipe is in good condition or to make necessary repairs.

Direct Current (DC)

Direct current refers to an electrical current that flows in only one direction. As an example, direct current is the form of electricity we get from flashlight batteries.

Technically speaking: Direct current is a form of electricity in which the polarity or direction of the current stays constant with respect to time (as opposed to alternating current). Direct current is typically used in impressed current cathodic protection systems because of its ability to maintain a constant polarity for the pipe's protection.

Direct Observation

Observation of an unqualified individual(s) during the performance of a covered task by an individual who is qualified to perform the task at hand. The observer must be in direct visual and verbal contact with the individual(s) and must be able to take immediate and effective corrective action if incorrect procedures or abnormal operating conditions are observed.

Disbonded Coating

Disbonded coating refers to any loss of bond or adhesion between the protective coating applied to the outside of a steel pipe and the pipe itself. Disbondment can result from adhesive failure, chemical attack, mechanical damage, hydrogen concentrations or other causes.

Discovery of a Condition

Discovery is the instance of discovering something or recognizing it for the first time.

Technically speaking: Under the Pipeline Integrity Management requirements found in the Code of Federal Regulations, 'discovery' refers to the point in time at which an operator has adequate information about a defect, anomaly, or other pipeline feature to determine the need for repair. Depending on the circumstances, adequate information may be available when a preliminary inline inspection (ILI) report is completed, following an analytical evaluation that integrates information from other sources, following excavation of the pipeline and observation of a condition, or following receipt of the final ILI report.

Distribution Line

A distribution line is a line used to supply natural gas to the consumer. A distribution line is located in a network of piping located downstream of a natural gas transmission line. As defined in natural gas pipeline safety regulations, a distribution line is a pipeline other than a gathering or transmission line.

Document

Prepare a retrievable record.

DOT

See Department of Transportation.

Double Submerged Arc Welded (DSAW) Pipe

Double-submerged arc-welded pipe is pipe produced from a flat piece of steel of which the edges are rolled together, to create a tube or pipe, and then connected or 'fused' together utilizing a specific process known as double-submerged arc-welding.

Technically speaking: Double-submerged arc-welded pipe is pipe having a longitudinal or spiral seam produced by at least two weld passes, including at least one pass each on the inside and outside of the pipe. The molten weld metal is shielded by a blanket of granular, fusible material used to reduce the impurities (slag) introduced from the surrounding air. Mechanical pressure is not used and filler metal for the inside and outside welds is obtained from the electrode(s). Use of DSAW in pipe fabrication is required by some pipe design standards, e.g., ASTM A-381, API 5L.

Durability

Durability refers to the ability of a material to resist wear and tear.

Technically speaking: Durability is the ability of a material to resist fatigue, which is a weakening of the material resulting from the repeated application and removal of stress. Pipelines experience fatigue as a result of periodic increases (application of stress) and decreases (removal of stress) in operating pressures. Durability refers to the pipe's ability to resist fatigue and continue to perform its required function.

EA

See Environmental Assessment.

Easement

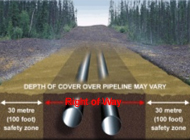

An easement is an acquired privilege or right, such as a right-of-way, afforded a person or company to make limited use of another person's or company's real property. For example, the municipal water company may have an easement across your property for the purpose of installing and maintaining a water line. Similarly, oil and natural gas pipeline companies acquire easements from property owners to establish rights-of-way for construction and operation of their pipelines.

EFRD

See Emergency Flow Restricting Device.

EIS

See Environmental Impact Statement.

Electric Resistance Weld (ERW) Pipe

Electric resistance weld (ERW) pipe is pipe produced from a flat piece of steel of which the edges are rolled together, to create a tube or pipe, and then connected or 'fused' together utilizing a specific process known as electric resistance welding.

Technically speaking: Electric resistance welding is a method used for making pipe in which the two edges of a curved plate of metal are heated by passing an electric current through them and the edges are then forced together to create a solid longitudinal weld, thus turning the plate into a section of pipe. Prior to 1970, much ERW welded pipe was produced using low frequency welding technology that can be more prone to seam failure than the high frequency welding technology adopted by most pipe manufacturers by 1970.

Emergency Flow Restricting Device (EFRD)

An emergency flow restricting device is a device used to restrict or limit the amount of oil or gas that can release out of a leak or break in a pipeline. Check valves and remote control valves are types of EFRDs.

Emergency Response

Operator qualification requirements for emergency response are limited to that portion of the response performed on the pipeline facility, rather than at offsite locations remote from the facility (e.g., deploying booms miles away is not a “covered task”).

Fire departments and other public responders are not required to be qualified and (if not qualified) must not perform covered operations or maintenance tasks on the pipeline facility.

All other individuals employed by the operator shall be qualified to perform their assigned covered tasks or shall be under the direct observation of a qualified individual.

Covered emergency response tasks are those tasks listed in § 192.615(a) and § 195.402(e) that meet the four part test specified in § 192.801 and § 195.501.

Emergency Response Personnel

Emergency response personnel are persons engaged in the immediate response to accidents and emergencies. Emergency response personnel can include firefighters, police/sheriffs, medical personnel, civil defense and emergency management personnel, and, sometimes, military, manufacturing and transportation personnel. Emergency response personnel are sometimes referred to as 'emergency responders' and 'first responders.'

Encroachment

Encroachment refers to the unauthorized use of a right-of-way in violation of the terms by which the right-of-way was established (e.g., easement).

Environmental Assessment (EA)

An environmental assessment is an evaluation required by the National Environmental Policy Act (NEPA) to determine whether a Federal action (major projects or legislative proposals) would significantly affect the environment. If the Environmental Assessment concludes that the Federal action could significantly affect the environment, a more detailed Environmental Impact Statement must be produced. If not, a Finding of No Significant Impact (FONSI) is filed.

Environmental Impact Statement (EIS)

An Environmental Impact Statement is a document required of federal agencies, by the National Environmental Policy Act (NEPA), for major projects or legislative proposals significantly affecting the environment. A tool for decision making, it describes the positive and negative effects of the undertaking and cites alternative actions.

Technically speaking: An Environmental Impact Statement is preceded and determined by an environmental assessment. An EIS must include a description of: (1) the environmental impact of the proposed action, (2) any adverse environmental effects which cannot be avoided should the proposal be implemented, (3) alternatives to the proposed action, (4) the relationship between local, short-term uses of the environment and the maintenance and enhancement of long-term productivity, and (5) any irreversible and irretrievable commitments of resources which would be involved in the proposed action should it be implemented.

Environmentally Sensitive Area (ESA)

An environmentally sensitive area is an area of environmental importance that is sensitive to environmental damage from a liquid pipeline release. (Reference 49CFR 195.2).

Evaluation

As defined in § 192.803 and § 195.503. Note: Any evaluation of an individual’s qualifications must follow an objective, consistent process that documents the individual’s ability to perform the covered task, including the ability to recognize and react to AOCs.

Evaluator

Persons performing evaluations should possess the required knowledge (1) to ascertain an individual's ability to perform the covered tasks and (2) to substantiate an individual's ability to recognize and react to abnormal operating conditions that might surface while performing those activities. This does not necessarily mean that the person performing the evaluations should be physically able to perform the covered tasks themselves.

Event

An event is a significant occurrence or happening. As applicable to pipeline safety, an event could be an accident, abnormal condition, incident, equipment failure, human failure, or release.

Event Sequence

An event sequence is a specific, unplanned series of events composed of an initiating event and subsequent, intermediate events that lead to a result, such as a pipeline accident.

Event Tree

An event tree is a logic diagram that is used to identify and analyze individual events and event sequences that can or did lead to a singular, usually larger, event of interest, such as an accident. It is called a tree because on the diagram each individual event is shown on a branch connected to a trunk that leads to the accident. Event trees are powerful analysis tools that can help determine the cause of an accident or anticipate and prevent failures.

Excavation

Excavation refers to any operation involving movement of earth, rock or other materials below existing grade or surface level. Excavation can include digging, blasting, boring, tunneling, and backfilling.

Excavation within a Pipeline Facility

Qualification for this covered task does not require the Operator's employee or contractor employee to be proficient in the operation of excavation equipment. Covered task(s) requiring qualification shall address the following:

- Verification of line location and depth

- One-call and underground facility owner/operator notifications

- Proper techniques to avoid pipeline damage

- Sloping/shoring

- Water removal

- Inspection

Third party excavations that take place on the operator's pipeline facility shall be handled in accordance with the operator's damage prevention program requirements.

External Force Damage

See Outside Force Damage.

Failure

Failure is a condition in which a human, structure, component, device, or system fails to adequately perform its intended purpose.

Technically speaking: While a pipeline that is actually leaking product is the most obvious indication of failure, failure is often also defined as the point at which the pipe material is stressed beyond its elastic or yield point. At that point the material is deformed and does not return to its original shape. A pipeline rupture is an example of this type of failure.

Failure Frequency

Failure frequency is the rate at which failures occur.

Technically speaking: The number of failure events that occur divided by the total elapsed calendar time during which those events occur or by the total number of demands, as applicable.

See also Failure Rate

Failure Probablilty

Failure probability is the probability that a failure will occur.

Technically speaking: Failure probability is the probability that a structure, device, equipment, system, etc. will fail on demand or will fail in a given time interval, expresse

Fatigue

Fatigue is the weakening of a material caused by the repeated application and removal of stress. For example, if you bend a piece of metal back and forth repeatedly in the same spot, fatigue will result at the bend location and will weaken the metal until it eventually breaks.

Technically speaking: Pipelines experience fatigue as a result of periodic increases (application of stress) and decreases (removal of stress) in operating pressures. Because fatigue can cause a failure to occur at stress levels well below those that a material can withstand in a single, non-repetitive loading, materials that must resist repeated stress cycles must be specially designed for this service. Durability is the ability of the material to resist fatigue.

Fault Tree

A fault tree is a logic diagram that is used to identify and analyze potential causes or failures that can or did lead to an event. It is called a tree because each possible fault or cause is shown as a branch on a trunk that leads to the accident.

Technically speaking: A fault tree is a logic model that graphically portrays the combinations of conceivable human or mechanical failures (or faults) and events that can or did eventually lead to a specific result or consequence of interest. Fault trees are powerful analysis tools that can help determine the cause of an accident or anticipate and prevent failures.

Fault Tree Analysis

Fault tree analysis is a logical, structured process using cause and effect or fault tree diagrams to determine the causes of an event. Fault tree analysis can help identify potential and contributing causes of failures before or after the failures actually occur.

Federal Energy Regulatory Commission (FERC)

From the web site of the Federal Energy Regulatory Commission:

The Federal Energy Regulatory Commission is an independent regulatory agency within the Department of Energy that - regulates the transmission and sale for resale of natural gas in interstate commerce; - regulates the transmission of oil by pipeline in interstate commerce; - regulates the transmission and wholesale sales of electricity in interstate commerce; - licenses and inspects private, municipal, and state hydroelectric projects; - oversees related environmental matters; - administers accounting and financial reporting regulations and conducts of jurisdictional companies; and - approves siting and abandonment of interstate pipeline facilities.

FERC

See Federal Energy Regulatory Commission.

Finding of No Significant Impact (FONSI)

A Finding of No Significant Impact is a document prepared by a federal agency showing why a proposed action would not have a significant impact on the environment and thus would not require preparation of an environmental impact statement. An FONSI is based on the results of an environmental assessment.

Final Order

After an operator has been given an opportunity to respond to a Notice of Probable Violation, the Associate Administrator for Pipeline Safety issues a Final Order, making findings of fact and ordering appropriate relief, if any. Civil penalties may be assessed and/or the operator may be required to comply with specified corrective actions. Only after PHMSA verifies that all corrective actions specified in Compliance Orders have been successfully completed and/or civil penalties paid are Final Orders considered "closed". Final Orders are described in 49 CFR 190.213.

FONSI

See Finding of No Significant Impact.

Fracture Toughness

Fracture toughness is the ability of a material (e.g., steel pipe) to resist stress and prevent cracks in the material from spreading.

Technically speaking: Fracture toughness is the ability of a material to deform under increasing tensile stress in the presence of a defect or crack without exhibiting rapid and extensive fracture propagation. Materials that have high fracture toughness can absorb larger amounts of energy (i.e., can withstand higher pressures or levels of stress) before an existing crack spreads.

Frequency

The number of events that are observed or are predicted to occur over a period of time.

Gas

In general, gas is the vapor state of a substance. Gas is distinguished from the solid and liquid states by relatively low density and viscosity, relatively great expansion and contraction with changes in pressure and temperature, the ability to diffuse readily, and the spontaneous tendency to become distributed uniformly throughout any container.

Technically speaking: As used in pipeline safety regulations (Reference 49CFR 192) gas is considered to be natural gas, flammable gas, or gas which is toxic or corrosive. Gases are normally compared to air in terms of its density. Since the specific gravity of air is 1.0, any gas with a specific gravity less than 1.0 will rise and usually disperse. Gas having a specific gravity greater than 1.0 will fall and collect near the ground or in low lying areas such as trenches, vaults, ditches, and bell holes. Such occurrences can be hazardous to human health and safety.

Gas Technology Institute (GTI)

From the web site of the Gas Technology Institute:

A membership organization that performs technical/research services for its members. GTI provides energy and environmental products and services with a focus on natural gas. Programs of this kind allow organizations to out-source all or part of their technology function and implement technology solutions to gain competitive advantage.

Gathering Line

Gathering lines are pipelines that transport oil or natural gas from the wellhead to a transmission line.

Technically speaking: For gas pipelines, a gathering line is a pipeline that transports gas from a current production facility to a transmission line or main (49CFR 192.3). For hazardous liquid pipelines, a gathering line is a pipeline that is no more than 8 5/8 inches (219.1 mm) in diameter and transports petroleum from a production facility (49CFR 195.2).

Geographic Information System (GIS)

A geographic information system is a combination of computer hardware, software, and data that is used to capture, maintain, analyze, and display information related to the geographic location of features and facilities. Geographic information systems are often used by pipeline operators to display information related to the location of their pipelines and the geographic features of the land surrounding their lines.

Geometry Tools

Geometry tools are inline inspection tools that are used to identify changes in the internal shape/diameter of a pipeline. Changes in the internal shape or diameter of pipe can be caused by dents, wrinkles, ovality, bend radius and angle, and occasionally indications of significant internal corrosion.

GIS

See Geographic Information System.

Global Positioning System (GPS)

Global Positioning System is a satellite navigation system funded and controlled by the U. S. Department of Defense (DOD). While there are many thousands of civil users of GPS world-wide, the system was designed for and is operated by the U. S. military. GPS provides specially coded satellite signals that can be processed in a GPS receiver, enabling the receiver to compute precise position, velocity and time. The space segment of GPS consists of the GPS satellites that send radio signals from space. The nominal GPS Operational Constellation consists of 24 satellites that orbit the earth in 12 hours. There are often more than 24 operational satellites as new ones are launched to replace older satellites. Four GPS satellite signals are used to compute the position of a receiver in three dimensions and the time offset (velocity) in the receiver clock.

Hazard

A hazard is a condition or substance that has the potential to produce harmful effects.

Hazard and Operability Analysis (HAZOP)

A hazard and operability analysis is a systematic method for evaluating hazards. It often involves the review of detailed system drawings, specifications, and operating procedures. Process hazards and potential operating problems are identified through a qualitative investigation of deviations from normal process conditions.

Hazardous Liquid

A hazardous liquid is a liquid that is dangerous to human health or safety or the environment if used incorrectly or if not properly stored or contained. Pipeline safety regulations identify petroleum, petroleum products, or anhydrous ammonia as hazardous liquids. (Reference 49CFR 195.2).

Hazardous Liquid Trunkline

A hazardous liquid trunkline is a main transmission pipeline that transports hazardous liquids.

Technically speaking: A hazardous liquid trunkline is a hazardous liquid transmission pipeline other than a flow line, gathering line, or in-plant pipeline.

Hazardous Material

A hazardous material is any substance or material that is dangerous to human health or safety or the environment if used incorrectly or if not properly stored or contained.

Hazardous Site

A hazardous site is the location of a hazard. This includes locations where hazardous materials are used, stored, transported or produced. It could also include a location where a hazardous liquid has been accidentally released.